Looking for the latest news and information on noise exposure, healthy hearing habits, hearing protection and more? From OSHA requirements to NIOSH guidelines and other best practices, CavCom keeps you in-the-know and up-to-date.

Filtered Articles › reset

Most Popular

Most PopularCavCom Receives 2024 OH&S New Product of the Year Award for Talk Through Your Ears® 7000

Most Popular

Most PopularCavCom Receives 2023 Hearing Technology Innovator Award for Talk Through Your Ears® for TeamTalk™

PAPRs and Communication

Two-Way Radios vs. Cell Phones: Which Is Better for Your Team?

Common Two-Way Radio Questions: Tips from the CavCom Team

FCC Licensing Process with CavCom

What is an FCC License?

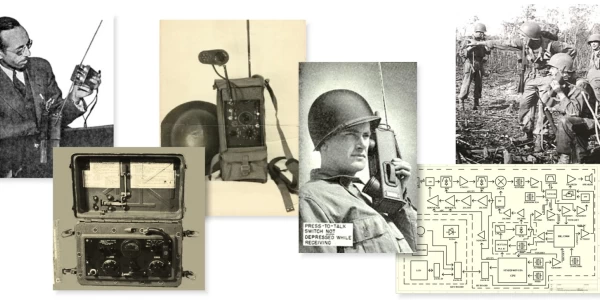

The History of the Walkie-Talkie

Walkie Talkies VS Two-Way Radios

Choosing a UHF or VHF Radio