How do CavCom‘s high-fidelity filters work and how are they different from traditional filters and vents?

Rather than blocking airborne particles of different sizes like a respirator, an acoustic filter passes or blocks different frequencies of sound. Closing off the earcanal, such as when wearing a typical earplug, suppresses the earcanal's natural amplification of high frequency sounds. In addition, subtle leaks around a hearing protector let through more low frequency sounds (with larger wave lengths) than high frequency sounds (which have very short wave-lengths). Since the attenuation (reduction) of sound is less at low frequencies than high frequencies, the result of wearing a typical earplug or earmuff is that incoming sound is distorted or unbalanced – the "bass" louder than the "treble." When it comes to speech, high frequency consonants are attenuated more than lower frequency vowels, resulting in a perception of mumbled or muffled speech.

To achieve a more even, or "uniform," attenuation of sounds across all frequencies, it is necessary to control sound leakage around the hearing protector to ensure the correct attenuation at low frequencies. At the same time, attenuation at high frequencies must be limited in order to achieve a more balanced sound quality. Specialty high fidelity filters are made by using a membrane which seals the ear but at the same time vibrates well at high frequencies to achieve a consistent amount of sound reduction across low and high frequencies.

CavCom‘s high-fidelity acoustic filters use a patented membrane technology to achieve the desired uniform attenuation result. Compared to open vents or small resistive tube technology, our filters have a relatively large aperture that allows more natural sound transfer across the mesh layers inside the filter. Since the membrane is made of a breathable material, there is also less occlusion effect or "plugged up" sensation. Discomfort and over-protection are two of the main factors that result in failure to use hearing protection properly. Our advanced technology is tuned specifically for comfort and to maintain natural hearing of speech and other important sounds in the workplace.

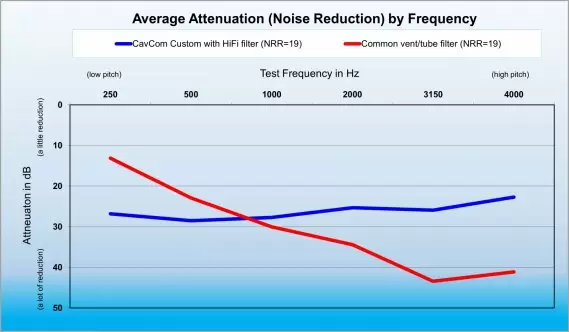

Example: Compare the performance of CavCom‘s Hi-Fi filter to a traditional vent/tube filter in the graph below. Both hearing protectors have an overall NRR of 19, but the tube filter (plotted in red) provides an uneven amount of protection – very little reduction at low frequencies (pitches) and a great deal of reduction at high frequencies. This results in significant distortions, perceived as mumbled speech or a "boomy" quality to sounds. In contrast, the CavCom filtered hearing protector (plotted in blue) provides a fairly even/uniform amount of reduction throughout the frequency range. This preserves the integrity of the original speech signal or other environmental sounds outside the ear. Listeners report "crispness" of sounds and improved speech intelligibility.

To learn more about avoiding OVERPROTECTION, read our SoundBytes article.

Contact CavCom to learn more about high fidelity filters to help improve communication, safety and efficiency in your moderate noise environments and hearing-critical jobs.

How often should custom earplugs or earsets be replaced?

Not all custom products are the same. CavCom‘s custom earplugs and earsets are designed to last many years due to the considerable strength and durability of our design and materials. Replacement is not based on a set expiration date, but instead should be approached on an as-needed basis. Users should routinely check for wear and tear and proper seal of the ear. If an earpiece is broken or no longer adequately seals the ear, a replacement can be made.

In most cases, CavCom‘s digital storage of ear impressions allows remakes to be made from data already on file for each worker. A new ear impression may be needed to address any significant changes to a user's ear canals resulting from substantial weight change, injury to ear, etc.

For more information about custom products, see this article from CavCom‘s SoundBytes newsletter. Please contact us if you have questions or need guidance on ordering replacement custom products for your employees.

What is NRR or Noise Reduction Rating?

The Noise Reduction Rating (NRR) is a laboratory-derived single-number rating designed to characterize a hearing protector's noise reduction capabilities. The level of noise entering a person's ear, when the hearing protector is well-fitted and worn as directed, is approximated by the difference between the environmental noise level and the NRR (A-weighted environmental noise measurements must be corrected by subtracting 7 dB). A more precise estimate of field performance can be provided by Individual Fit Testing. This personalized test is performed under typical wear conditions and results in a Personal Attenuation Rating (PAR) for each worker.

For more information, see our SoundBytes article.

What is the Personal Attenuation Rating (PAR)?

Personal Attenuation Rating (PAR) is a measure of hearing protector attenuation for each worker as determined by Individual Fit Testing. Individual Fit Testing is conducted for each employee using his/her own hearing protector as normally worn. OSHA, NIOSH and many professional organizations have long recognized that the laboratory-derived NRR is not a good predictor of actual hearing protector performance in the real world. Individual Fit Testing is now a recommended best practice for hearing conservation programs.

For more information, see our SoundBytes article.

Why do OSHA formulas require us to subtract 7 dB from the Noise Reduction Rating (NRR)?

The 7dB reduction is a correction to be used with the employee's A-scale noise measurements. Most people are surprised to learn that the current NRR system was developed in the 1980s for use with C-scale workplace noise readings (the C-scale is a broad-spectrum frequency setting on sound level meters and dosimeters). Employee time-weighted-average noise exposures, however, must be calculated with an A-scale frequency setting on the sound measurement equipment (the A-scale is a weighted frequency setting more closely matched with human damage-risk criteria). The bottom line: if the employer has A-scale noise information, but not C-scale, then a 7 dB correction factor is required when using the NRR to assess hearing protection for the workplace.

For more information, check out our SoundBytes newsletter article, The NRR: What's in a Number?

Does OSHA require hearing protection de-rating (cut the Noise Reduction Rating (NRR) in half)?

It is a common misconception that OSHA requires employers to "de-rate" NRRs by 50% when assessing adequacy of the hearing protector for the worker's noise exposure. Instead, OSHA only requires applying a 50% "safety factor" when considering whether engineering controls are to be implemented. For determining compliance with basic hearing conservation program requirements, however, OSHA does not require de-rating the NRR (or NRR - 7 when the company uses A-scale noise measurements).

The background is that de-rating schemes were developed decades ago and generally are no longer deemed helpful. Instead, individual hearing protection fit testing is now considered best practice for verifying real world performance.

For more information, see the explanation provided in the OSHA Technical Manual Section III: Chapter 5, Appendix F: Noise Reduction Rating

Read more in our SoundBytes articles:

Why should we conduct hearing protection fit testing?

Hearing protection fit testing is now considered best practice for any occupational health and safety program. Benefits of fit testing include:

- Selecting the style and size hearing protector that is appropriate for each worker's noise exposure, work environment and personal preferences

- Verifying the amount of protection provided in the real world instead of relying on outdated de-rating calculations of laboratory NRR values

- Proactively identifying workers with poorly-fitting hearing protectors who are at increased risk of developing hearing loss/shifts in hearing

- Improving employee knowledge of hearing protector fit and use, leading to greater motivation for personal safety

- Accomplishing required follow-up in cases of Standard Threshold Shift (STS) and other significant shifts in hearing by verifying refit and retraining of hearing protection devices

- Producing written documentation of your hearing loss prevention efforts

For more information:

How often should we conduct hearing protection fit testing?

To best accomplish your hearing loss prevention goals, most companies follow these general rules of thumb for fit testing/retesting:

- new employees and those new to the hearing conservation program

- when a worker changes to a new type of hearing protector

- when an employee has shown Standard Threshold Shift (STS) or other significant shift in hearing

- in cases of physical changes to the ear such as injury, surgery, etc. that affect the fit of the hearing protector

- when a worker expresses concerns or complaints about hearing protector fit/attenuation

- some employers conduct routine retesting (every few years for example) for all employees, while others choose to target routine retests only for individuals with very high noise exposures (using dual hearing protection), for those working hearing-critical jobs, or those who have experienced past shifts in hearing or other concerns

For more information:

Individual Fit Testing for Hearing Protectors

How Individual Fit Testing Can Complement Your Hearing Conservation Program

Is it true that OSHA requirements do not apply to custom hearing protectors?

Although it is true that a well-made custom hearing protector typically performs better in the real world than pre-sized or one-size-fits-most formable earplugs, we can assure you there is no formal "exemption" policy from OSHA for custom products.

We know hearing protector attenuation is an important factor in the success of your hearing conservation program. That's why CavCom strongly recommends conducting individual fit testing to obtain Personal Attenuation Ratings (PARs), not relying solely on mathematical estimates of laboratory Noise Reduction Ratings (NRRs).

For further guidance on assessing the amount of hearing protection your workers are receiving, see these article from CavCom‘s SoundBytes newsletter:

NRR De-Rating Schemes are Outdated

Please contact us if you have questions or would like guidance on hearing protection attenuation and individual fit testing.

Will wearing earplugs make my ears ring?

The short answer is "no." What is much more likely is that a person already has tinnitus (ringing in the ears), but doesn't notice the ringing so much when surrounded by typical day to day sounds. However, the ringing becomes much more noticeable when the environment is very quiet (such as at night) or when wearing earplugs or earmuffs. In either case, ambient/background noise is reduced, and ringing in the ears is now more audible and unfortunately, more annoying.

Because wearing earplugs or earmuffs is necessary to protect your hearing against loud noise, it may take some getting used to when first wearing hearing protectors. Most people report the tinnitus lessens as they get used to wearing hearing protection (and as ears are better protected against the effects of noise). The alternative is far worse – failing to wear hearing protection in loud noise can lead to permanent hearing loss and progressively worse tinnitus over time. If your tinnitus is severe or getting worse, check with a medical professional.

To learn more about causes, possible treatments, and work-arounds like white noise maskers, see our SoundBytes article.

What are noise-cancelling hearing protectors?

We sometimes hear about Active Noise Reduction (ANR), or "noise cancellation," in association with electronic earmuffs. This electronic technology uses a microphone to pick up incoming sound, a digital processor to invert the phase of the incoming sound, and a speaker to reintroduce the altered sound. The intent is to reduce the resulting sound levels by "cancelling" as much of the original sound wave as possible.

Because of the practicalities of basic acoustics, however, this technique works well only for noises with relatively long wave-lengths, that is, low frequency (pitch) sounds. In practice, ANR technologies effectively reduce levels when sounds are about 500 Hz and below. Consumer headsets are popular for reducing annoying, but not hazardous, day-to-day noise from cars, airplanes, and so on. In industry, hazardous noise environments are generally comprised of many frequencies, or "broad band" sound. Although ANR can often supplement noise reduction and hearing protection efforts in high noise environments, the technology typically cannot stand alone. ANR is usually applied only in combination with traditional hearing protection methods (such as earplugs and earmuffs) that are effective at blocking a wide frequency range of noise.

What is the Noise Reduction Rating (NRR) for double hearing protection?

The OSHA Technical Manual allows employers to add 5 dB for the second hearing protector when an earmuff and earplug are worn together. An example: if wearing an earplug with an NRR of 25 together with an earmuff (also with an NRR of 25), expect a combined NRR of 30. Keep in mind, however, that this rule of thumb is a general estimate. To learn more about the ins and outs of dual hearing protection, and how to improve accuracy of your estimates, see this SoundBytes article.